Product Catalog

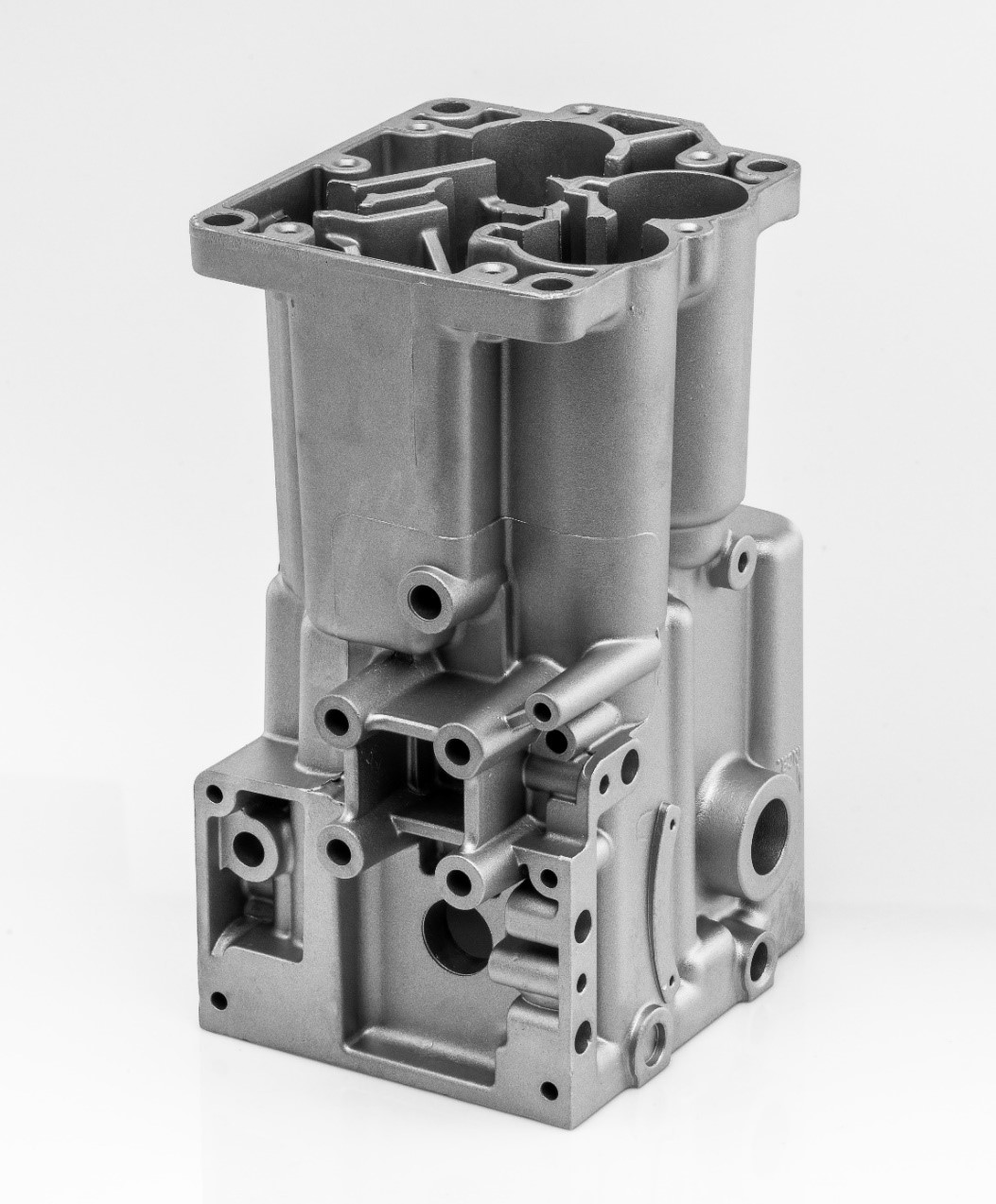

Part Description: Pipe Threading Machine Housing

Industry: Construction

Alloy: 383

Weight: 17 lbs.

Cavities: 1

Machine size: 1200 ton

Secondary Operations: Vibratory Deburr and sanding

This large casting is formed with 3 slides. Proper die thermal and process control is required to create a cosmetic finish on the entire outside of the casting.

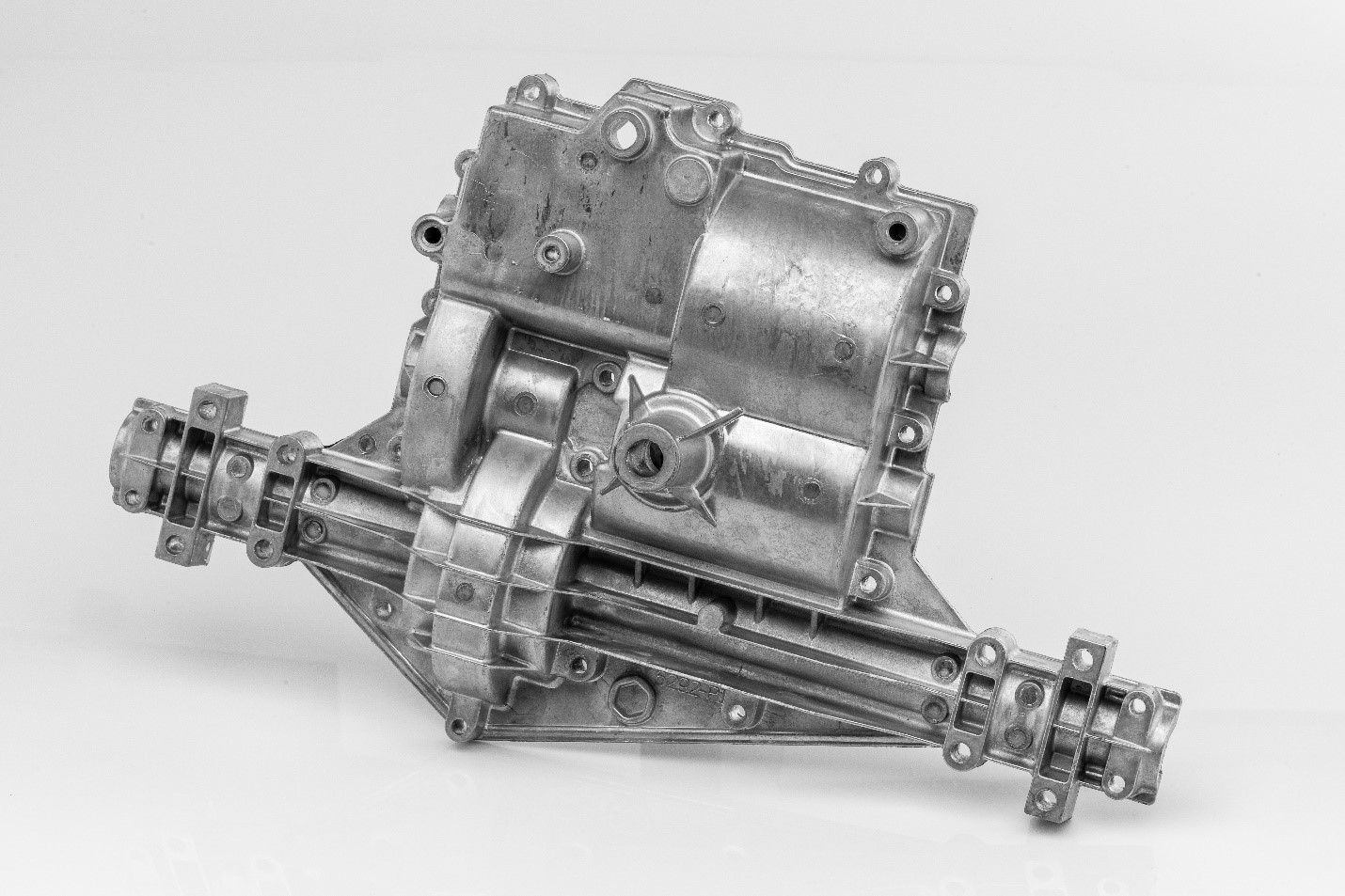

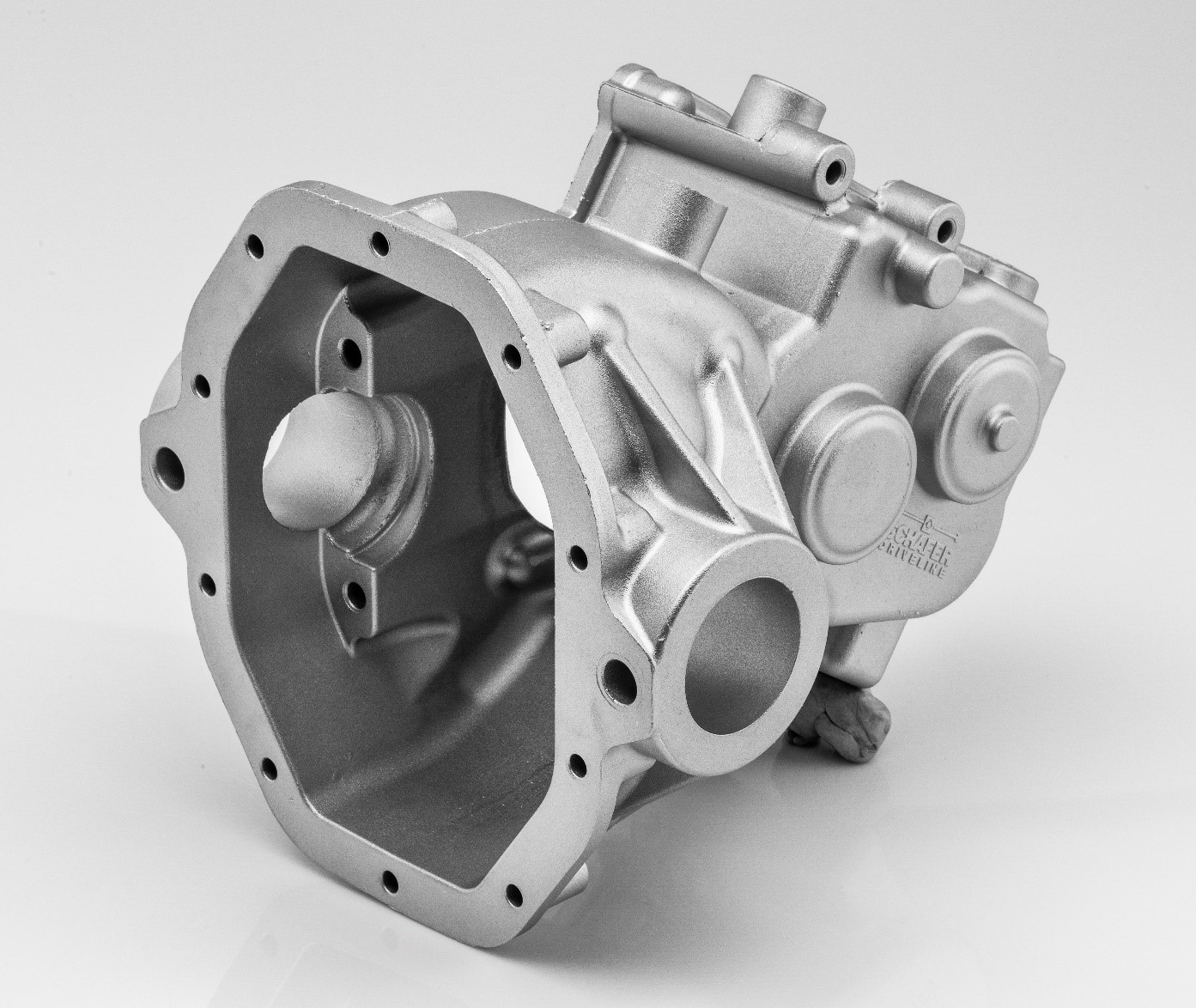

Part Description: Axle Housing

Industry: Off Highway

Alloy 383

Weight: 17.7 lbs.

Cavities 1

Machine size 1200 ton

This casting has a complex geometry with varying wall shapes and configurations. We performed over 50 filling and solidification simulations to optimize the runner and venting system. We produced high quality castings on the first sampling.

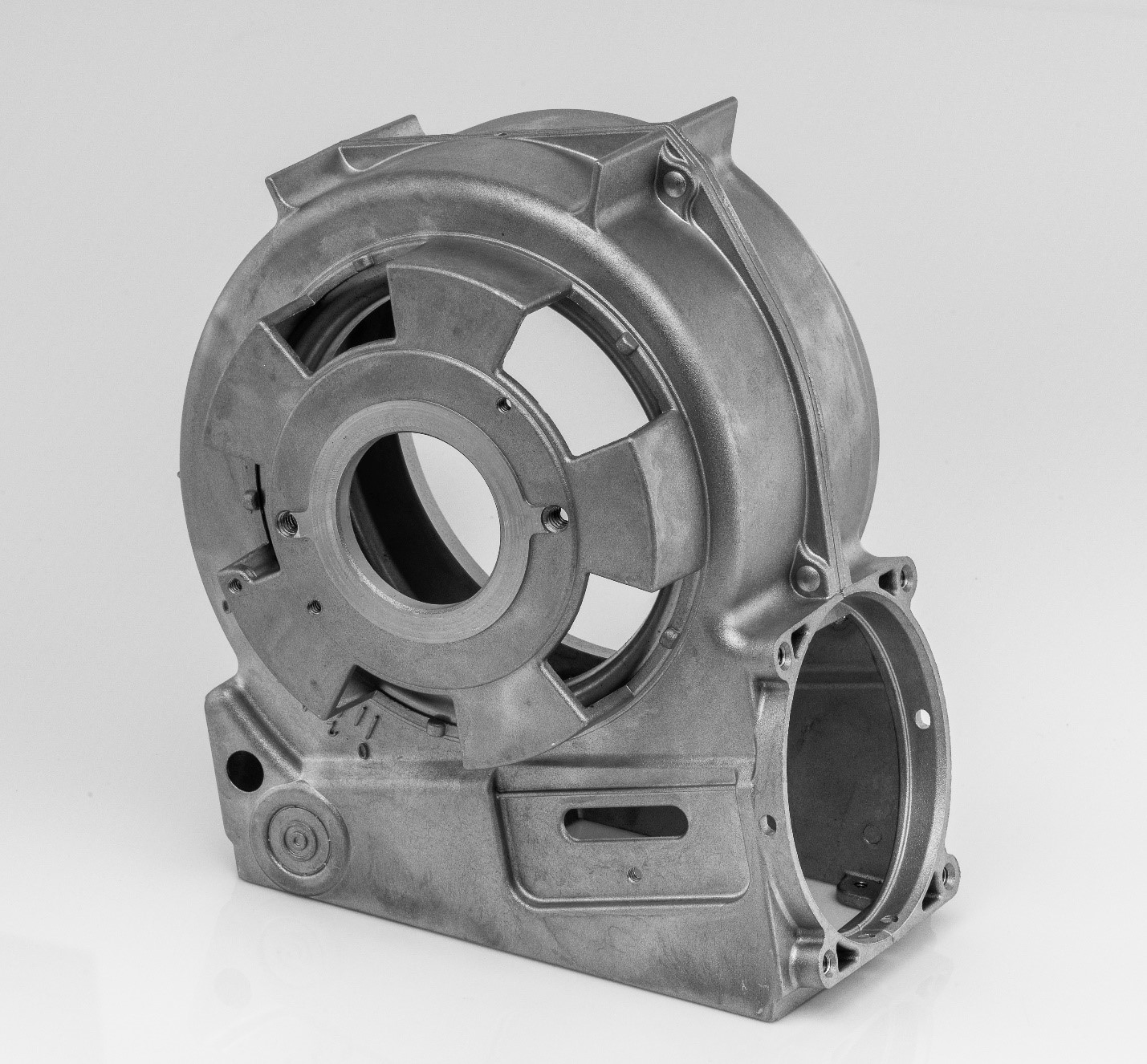

Part Description: Furnace Blower Housing

Industry: Residential Heating and Cooling

Alloy 383

Weight 2.5 lbs.

Cavities: 2 and 4 cavity family dies

Machine size 900 ton

Secondary Operations: Rivet, spin blast

The two halves of this housing are cast simultaneously in a family die. We rivet both halves together after die trimming. These thin walled castings have tight flatness tolerances to ensure a tight seal during operation.

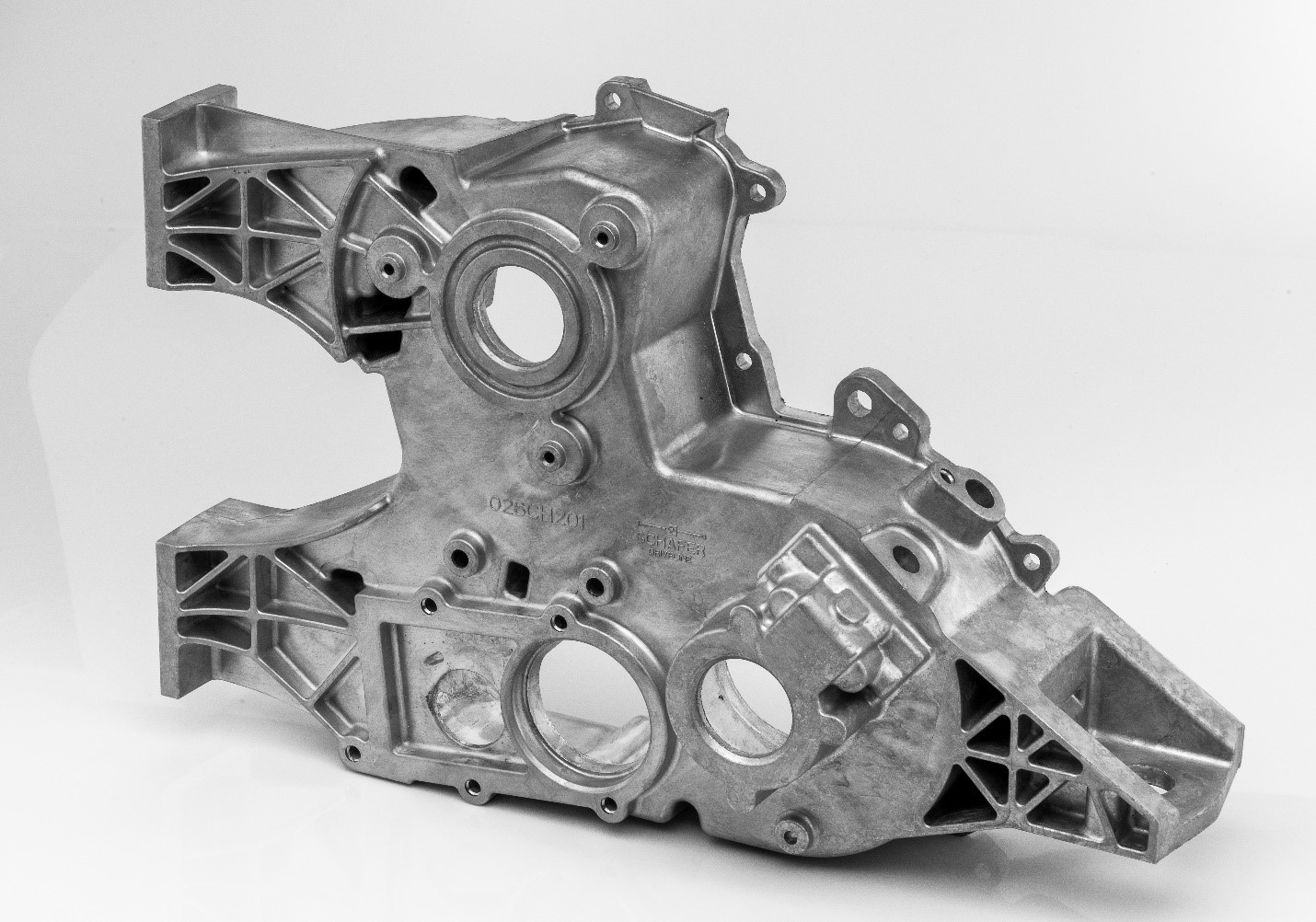

Part Description: Large Engine Governor

Industry: Construction

Alloy 383

Weight 10 lbs.

Cavities 1

Machine size 900 ton

Post casting operations: Vibratory deburr, sanding and reaming

This casting is produced with a complex 3 slide die. Two of the slides have intricate walls to form the functional areas of the governor.

Part Description: Brake Pump Housing

Industry: Automotive

Alloy 413

Weight .68 lbs.

Cavities 2

Machine size 600 ton

Pump housings must be pressure tight. 413 alloy creates the thickest pressure tight skin of any die cast alloy making it ideal for this application. Small diameter slide cores surrounded by heavy walls are thermally controlled using jet cooling to reduce porosity and solder.

Part Description: Axle Housing Cover

Industry: Commercial Lawn and Garden

Alloy 383

Weight 7 lbs.

Cavities 1

Machine size 900 ton

Secondary Operations: Spin Blasting

The internal feature of this casting is formed with a large slide which also functions are a secondary machining locating surface. The slide dimensions are held well within NADCA precision tolerances for this operation.

Part Description: Shift forks

Industry: Automotive

Alloy 380, 383, 390

Weight .5 lbs. -2 lbs.

Cavities 1-4

Machine size 600-900 ton

Secondary Operations: Tumble blasting

These castings require very tight cross parting line tolerances on multi-cavity dies to reduce secondary machining on the shifting surfaces.

Part Description: Connecting Rod

Industry: Transportation

Alloy 383 with a Dispal insert

Weight 1 lbs.

Cavities 4

Secondary Operations: Tumble blast, assembly and machining

The connecting rod is cast with a unique aluminum insert which is very high in silicon for wear resistance. We assemble and machine both castings in a secondary operation. The bores are machined to less than a 16 micro finish with a tolerance of +/- .006 microns

Part Description: Engine Oil Filter Housing

Industry: Aviation

Alloy 383

Cavities 1

Machine Size: 600 ton

Secondary Operations: Machining, Godfrey & Wing Impregnation and Pressure Test

A stainless steel insert is cast into this part. We mill the gasket seal surface, then use a form tool to hold the critical dimensions using a 5th axis CNC Mill. We use a CNC lathe to bore out the stainless steel insert, thread it, and machine the oil can surface. We cast this part with Fondarex vacuum to ensure a pressure tight casting.

Part Description: Air Muffler Caps

Industry: Industrial

Weight .05-1.0 lbs.

Alloy 383

Cavities 4-12

Machine Size: 600 ton

These castings are produced in family dies capable of producing dozens of varieties while minimizing the customers tooling cost. The castings are machined in automated dual spindle lathe.

Part Description: Actuator Body

Industry: Industrial

Weight .5-3.5 lbs.

Alloy 383

Cavities 1

Machine Size: 600 ton

Secondary Machining: Vibratory deburr, Machining, Impregnation, anodizing and paint

This part is machined on one of our 5th axis machines. This allows us to machine the part complete in one fixture and hold very tight True Position tolerances. The machined surfaces of this part must exhibit zero visible porosity. Several versions of this casting are produced using Fondarex Vacuum.

Part Description: Valve Body

Industry: Transportation

Weight .35 lbs.

Alloy 383

Cavities 2

Machine Size: 600 ton

Secondary Operations: Machining and anodizing

We use a CNC with progressive fixtures to machine this casting. Form tools are used to machine the ports to ensure all tolerances are met while minimizing cycle time. These castings are produced with Fondarex Vacuum to ensure pressure and porosity requirements are met.

Part Description: Solenoid Pilot Body

Industry: Electronics

Weight .735 lbs.

Alloy 383

Cavities 1

Machine Size: 600 ton

Secondary Operations: Vibratory Deburr and machining.

This part has an intricate slide geometry with extensive secondary machining with zero allowance for visible porosity. We use a CNC with progressive fixtures to machine this part. A form tool cuts 2 different features simultaneously.

Part Description: Tire Inflation Hubcap

Industry: Transportation

Weight 2 lbs.

Alloy 383

Cavities 2

Machine Size: 600 ton

Secondary Operations: Vibratory Deburr, Machine, Godfrey & Wing Impregnation and Anodize.

These castings are produced on 2 cavity dies with long slide cores. Dies are thermally controlled with the help of infrared imaging to minimize soldering that may cause leak paths.

This part is machined using one of our 4th axis machines. This casting has deep ports that require 32 micro finish after Impregnation and Anodizing. We were able to develop a form tool that not only holds the surface finish but also cuts other features at the same time.

Part Description: Bracket

Industry: Construction

Weight .285

Alloy 383

Cavities: 1

Machine Size: 600 ton

This part is machined on one of our 4th axis machines. This part is challenging to hold in the fixture due to its design. All bores on this casting are machined to a 32 micro surface finish along with other drilling, milling, and tapping operations.

Part Description: Shock Mount

Industry: Automotive

Weight 1 lbs.

Alloy 360 and 413

Cavities 6 and 10

Machine size 900 and 600

Secondary Operations: Tumble blast and roll forming.

The elastomer is inserted into the housing and roll formed together with a lid during a secondary operation performed at General Die Casters. The casting material must have exceptional integrity to withstand the roll forming process without failing.

Part Description: Floor Cable Poke – Thru Assembly

Industry: Construction

Weight 2 lbs.

Alloy 383

Cavities 1 and 2

Machine size 600

Secondary Operations: Machining, Anodize, E-Coat, Paint, Assembly

This assembly is produced with 7 different castings. GDC performs the assembly on a made to order process to reduce the customers inventory cost. The assemblies are finished in a variety of E-coat, Paint and anodize finishes.

Part Description: Electric Motor End Covers

Industry: Automotive

Weight .4-.8 lbs.

Alloy 383

Cavities 4, 6 and 8

Machine size 900 ton

Secondary Operations: Tumble blast and CNC machining.

These castings are produced on 8 and 12 cavity dies with tight cross parting line tolerance for CNC fixturing. These parts are machined using one of our fully automated lathes. While the part may look easy to machine its actually very challenging. These parts have very little surface area on the O.D. (approximately .100 of an inch) for the jaws to hold the casting. The chuck pressure along with the fixture design must be perfect or you will distort the casting.

Part Description: Transmission Retainer Ring

Industry: Automotive

Weight .25 lbs.

Alloy 383

Cavities 8

Machine size 900 ton

Secondary Operations: Tumble blast and CNC machining.

These parts are machined using a fully automated dual spindle lathe. We use Fondrex vacuum to produce these castings to ensure there is no visible porosity on the machined surfaces.

Part Description: T-Handle

Industry: Automotive

Weight .1 lbs.

Alloy 383

Cavities 12

Machine size 600 ton

Secondary Operations: Vibratory Deburr, Machining and paint.

We cast several versions of this part using interchangeable unit dies to reduce the customer’s tooling cost. We machine these castings in a controlled oversized state to allow the threads to be in tolerance after painting.

Part Description: Lever Assembly

Industry: Construction

Weight .1 lbs.

Alloy 383

Cavities 1

Machine size 600 ton

Secondary Operations: Drill, ream, broach, saw, press in inserts

This part contains two small cast in powdered metal inserts in a die with complex slide shut offs. We machine this part on our 5th axis CNC which gives us the ability to machine all features without it ever leaving the fixture. We machine the part in one set up and hold tighter than normal positional tolerances than if multiple setup/fixtures where used.

Part Description: Small Engine Cylinder

Industry: Lawn and Garden

Weight 1-2 lbs.

Alloy 383 and 390

Cavities 2 and 4

Machine size 900 ton

Secondary Operations: Heat Treating

The thin cooling fins require tight process controls to ensure proper filling. The thin die steel features combined with 390 alloy require strong tooling preventive maintenance program to ensure tool life goals are met.

Part Description: Small Engine Piston

Industry: Lawn and Garden

Weight .1-.2 lbs.

Alloy 390

Cavities 8-10

Machine size 600 and 900 ton

Secondary Operations: Heat Treating and tumble blast

High cavitation dies with tight dimensional and porosity requirements are required for pistons. 390 alloy must be closely managed to ensure primary silicon structure meets specifications.